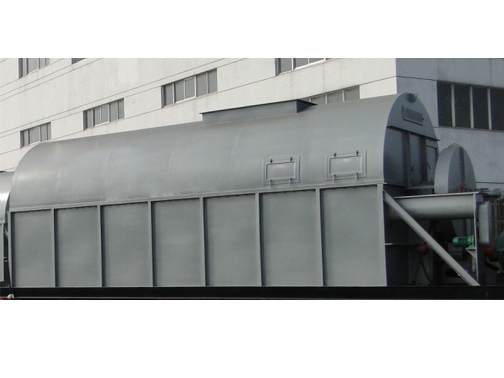

1、Advantages: low steam consumption, low electricity consumption, wide range of drying material, large output, large water evaporation, high moisture material which can dry, high drying elasticity(adjust drying time on different quality of material and requirement of water).

2、Purpose is fiber and germ drying

3、Low heat consumption, big output and continuous production

4、Wear parts of this machine is very few, convenient installation, cost of maintain is very few.

|

Type

|

GG80

|

GG100

|

GG120

|

GG150

|

GG200

|

GG300

|

GG400

|

GG500

|

GG600

|

|

Heat conduction area(m2)

|

80

|

100

|

120

|

150

|

200

|

300

|

400

|

500

|

600

|

|

Motor(kw)

|

5.5

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

37

|

55

|

|

Product

|

Feed water

|

Discharge water

|

Water/m2.h)

|

(kg steam/kg water)

|

|

Germ

|

55%

|

3-5%

|

2.5-3

|

1.25-1.5(饱和蒸汽) (3500-3800kj/蒸汽 kg 水)

|

|

Corn fiber

|

60%

|

10-12%

|

4.8

|

|

Protein

|

40%

|

12-13%

|

4.7

|

|

Potato fiber

|

65%

|

10-12%

|

4.8

|