Pumpthe fruit juice and jam into tubular heat exchanger, heating exchange through the shell steam or hot water, thus to heating or sterilizing fruit juice, you can set the heating temperature according to the process flow and product characteristics, tube diameter is very big, suitable for small particle fruit juice or jam.

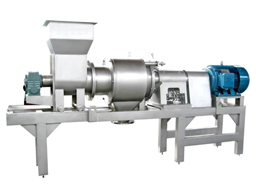

This equipment suitable for preheating and deactivation enzyme those crushed product like tomato, onion, pepper, apple, strawberry, blackberry, carrot etc.Tubular heater, also called enzyme inactivation, this equipment use the latest technology, throughhot water heating, which can effectively prevent steam heating material directly, and to prevent scaling problem which result by large material temperature difference.

Strong and stable equipment frame, strong welding technology, fine surface treatment, we use high quality stainless steel to make whole machine rack.