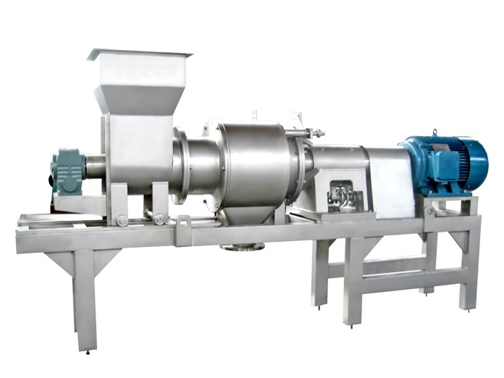

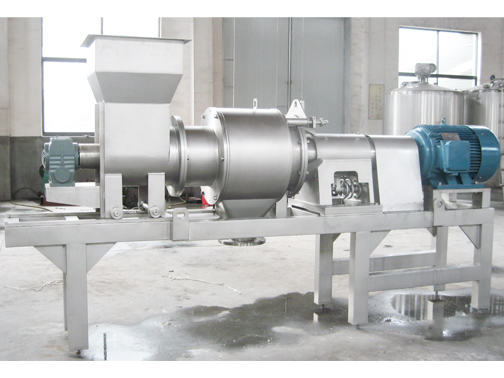

First transfer fruit or vegetable into the hopper, then deliver the material into the stator under screw conveyer motor drive, the stator can transfer the product evenly to the follow-up pulping rotor with blades, this pulping rotor rotary inside of coneshaped stainless steel screen, thus extractfruit juice and pulp,which can effectively separate the fruit flesh fromfruit peel, stems and seeds(we called cold extraction), this process does not require crusher; the coming out fruit puree can be pump into the efficient puree heat exchanger, it will deactivate enzyme from puree through heat treatment; after enzyme deactivation, it will be pumped into follow-up heat pulping and refining machine through screw pump,which will be refined (called heat extraction) under enzyme passivation temperature; and then pump productto concentration and filling section.

1.Compared with the traditional processing systems, it can reduce wastes obviously.

2.The puree will look more fresh, bright and yellow, butless red, which highly improve those red color skin fruit puree quality.

3.Oxidase‘s activity was greatly reduced and could therefore maintain the natural color of the fruit.

4.Compared with the hot extraction, enzyme passivation temperaturecan be lower.

5.Completely remove spots and effectively reduce natural brown spots.

6.Effectively reduce pesticide residues.

7.Reduce the working load for the subsequent process, thus reduce the residence time within the device.

8.All machine to be assembled under same rack, with compact structure, thus save space.

9.All operating parameters are automatically controlled by PLC and operator human machine interface.