Evaporated material recycle inside of the evaporator, mainly depend on the outer power generated forced fluidity. Recycle speed usually can reach to 1.5-3.5meters/second. Heat transfer efficiency and production capacity is big. Raw material liquid pump from up and down, which flow to the upper side of the heater. Steam and liquid blending material go into evaporator and then separate, steam will be discharged out from upper side, single effect steam go into condenser, and then discharge out. Fluid can be blocked and go down by gravity, it is suction by the recycle pump through round conical bottom, then go into heater and recycle. When material evaporatedto the necessary concentration, it is discharged out through material outlet. If it is multi effect evaporation, it will go into the next evaporation room to be evaporated to the necessary concentration, and to be discharged out.

1. Whole system with reasonable and beautiful design, stable operation,high efficiency,energy saving and low steam consumption.

2. Large concentration ratio, forced circulating type, which can evaporate high viscosity material and short the concentration time.

3. With special design,you can easily change effects through easy operation, to be applicable for making different product.

4. Low evaporation temperature, the heat can be fully used. The material heating is gentle, so it is applicable for concentration heat sensitive materials.

5. After forced circulating, the inner pipe heated averagely, heating transfer factor is high, which can avoid “dry wall” phenomenon.

6. The material can be separated after going into separator,which improve the separating effect, and it is flexible to operate.

7. The whole set equipment is quite compact, which need small space, and the layout is simple and smooth, which represent large whole set evaporating equipment developing direction.

8. Continuous materials inlet and outlet, and material liquid level and needed concentration can be automatically controlled.

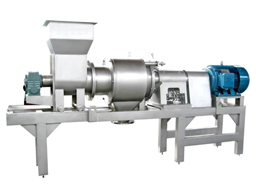

Triple effect forced circulating evaporator

Model and specification: SNQZ-XX

XX-moisture evaporation capacity (L/h): 6000、8000、12000、

15000、18000、36000、46000、55000、75000、90000、

110000

Double effect forced circulting evaporator

Model and specification: SNQZ-XX

XX-moisture evaporation capacity (L/h): 4000、5000、8000

Single effect forced circulating evaporator

Model and specification: SNQZ-XX

XX-moisture evaporation capacity (L/h): 1000、1500、2000

|

Model

|

Single-effect

|

Double-effect

|

Triple-effect

|

Four-effect

|

Five-effect

|

|

Water evaporating capacity Kg/h

|

500-2000

|

1200 -5000

|

3600-20000

|

12000-50000

|

20000-120000

|

|

density of inputting material%

|

Depending on different materials

|

|

Density of outputting material%

|

Depending on different materials

|

|

Steam pressure Mpa

|

0.05-0.1

|

0.6-0.8

|

|

Steam consumption Kg/Kg evaporation capacity

|

1.13

|

0.38

|

0.28

|

0.28

|

0.23

|