Falling film evaporation is to feeding material from its heating room upper side, flow through liquid distribution and film form device, uniformly distribute liquid to each heat exchange pipe, under the gravity, vacuum conducting, airflow effect, which formed film flow from up and down. During this flow period, the product is heated and evaporated by the inner shell heating medium, which the generated steam and fluid phase go into evaporators separating room, steam and liquid separated thoroughly, steam goes into condenser to be condensed ( single-effect operation) or go into the next evaporator room to be heating medium, thus realize multi-effect operation, fluid phase will be discharge out through separator.

1. Steam heating uniformly, it is with high heating efficiency and short heating time etc. advantage.

2.It can use waste heat as heating source, reducing steam consumption.

3.The distribution device distribute the material evenly in the heating pipe of the evaporator, material will flow as membranous from the upand down under the gravity, vacuuminduction and airflow effect, during suchworking process,the product heat exchange with the external heating tube steam and then to be evaporated.

4. The evaporation process is under vacuum condition, evaporation temperature is relatively low, and the evaporator is not easy to scaling.

5. It is suitable for foaminess material evaporation and concentration, as the material is evaporated as film form inside of heating tube, which separate the air and liquid, and pumping out large part product at the bottom of this machine at same time, only small part product goes into separator with the second effected steam to be separated again,There is small impact during whole product processing period, and it avoid to form bubbles.

6. For fruit juice or milk evaporation concentration, this equipment can have sterilize function, material pre-heat at first, then pump into sterilizer, when it reaches 90-125 degrees, holding for 30-60 seconds, then pump into the evaporator, productcan be quickly flash evaporated, temperature cool down instantly.

7.This equipment can have CIP cleaning system, to realize clean in place, easy operation and no dead corner.

8. We can install steam injection pump, decrease steam consumption, thus to save running cost.

9.Continuously feeding and discharging product.

10. We can make auto control system, which have complete configuration, operation, monitoring and control function, this system consists of communication interface, display alarm, report printing, control parts etc.,which can realize auto control material feeding, heating temperature, outlet concentration degree, cleaning.

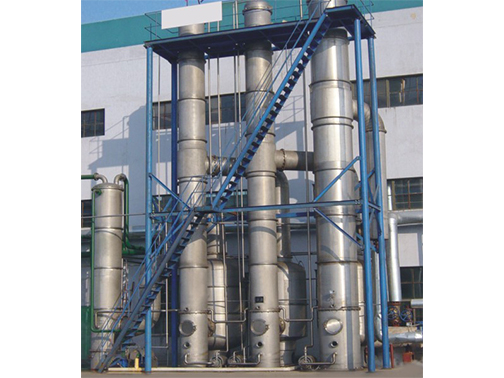

Triple effect falling film evaporator

Model and specification: SNJM03-XX

XX-Moisture evaporation capacity (L/h): 3600、5000、6500、

8000、10000、12000、20000

Double-effect falling film evaporator

Model and specification: SNJM02-XX

XX-moisture evaporation capacity (L/h): 1200、1500、2400、

3000、4000、5000

Single effect falling film evaporator

Model and specification: SNJM01-XX

XX-moisture evaporation capacity (L/h): 1000、1500、2000

|

Model

|

Single-effect

|

Double-effect

|

Triple-effect

|

Four-effect

|

Five-effect

|

|

Water evaporating capacity Kg/h

|

500-2000

|

1200 -5000

|

3600-20000

|

12000-50000

|

20000-120000

|

|

density of inputting material%

|

Depending on different materials

|

|

Density of outputting material%

|

Depending on different materials

|

|

Steam pressure Mpa

|

0.05-0.1

|

0.6-0.8

|

|

Steam consumption Kg/Kg evaporation capacity

|

1.13

|

0.38

|

0.28

|

0.28

|

0.23

|

|

Evaporating temperature

|

48-90

|

|

Sterilizing temperature ℃

|

86-110

|

|

Cooling water consumption T/T evaporation capacity

(Water input 20℃, water output 40℃)

|

28

|

9-14

|

7-9

|

6-7

|

5-6

|

·

Remarks: We can doing OEM order, design according to your requirement.