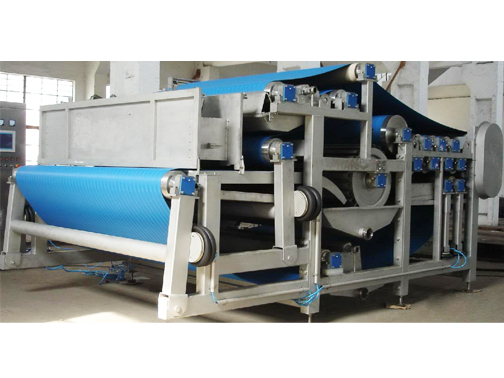

Those wet slag material continuously transferred to hopper through screw pump or conveyer (belt width can be adjustable), first filter out large part water through an independent concentration section, reduce product fluidity, then under internal and external two ringlike filter belt driving roll, screw press roll distribute product evenly, to be pre- press and dewater – low pressure dewater –butt clamp squeezing high pressure dewater, internal and external filter belt bypass several unit butt clamp squeezing roller with diminishing diameter, large part of water be squeezed gradually, which formed squeezable filter cake, discharge those strong force squeezed water from material, use water collection channel collect it and discharge, after internal and external filter belt separate, use wear resisting scraper device to scratch those filter cake (fruit residue) from internal and external filter belt surface. Finally use high pressure solid conical convex type clean spraying nozzle, form a fan cross hose to flush mesh belt, which to keep continuously dehydration effect.

1.This machine with the advantage of high squeeze efficiency, large working capacity, flexible operation and easy maintenance;

2.Use good grade high quality stainless steel and plastic material, main parts use abroad famous brand, make sure long term stable operation.

3.Continuous automatic working,airbag controlwater-fluctuation belt, correction, pressurization, frequency converterregulation speed;

4.Fully automatic CIP cleaning system,without manual operation, easy and convenient;

5.Control system with touch screen operation, intuitive interface, simple and efficient;

6.Energy saving, clean water filter from the arc screen, can be recycle use;

|

Parameter

|

Model

|

KADY-800

|

KADY-1200

|

KADY-1750

|

KADY-2500LR

|

KADY-2500HK

|

|

Output(t/h)

|

1~3

|

4~7

|

8~12

|

18~22

|

18~22

|

|

Belt Length(mm)

|

92000

|

14100

|

14500

|

14500

|

17200

|

|

Belt width(mm)

|

800

|

1200

|

1750

|

2500

|

2500

|

|

Juicing rate (Apple Juice)

|

≥75%

|

≥75%

|

≥75%

|

≥75%

|

≥75%

|

|

Roller Quantity(Roots)

|

20

|

20

|

20

|

20

|

20

|

|

Working Pressure(MP)

|

≤0.4

|

≤0.4

|

≤0.4

|

≤0.4

|

≤0.4

|

|

Main power(kw)

|

2.2

|

2.2

|

2.2

|

2.2

|

2.2

|

|

Cloth Power(kw)

|

0.25

|

0.37

|

0.37

|

0.55

|

0.55

|